Ball Screw Support Unit

Introducing our versatile range of ball screw support units, designed to meet the specific needs of your light, medium, and heavy load equipment. These units are essential for securing and stabilizing the left and right ends of your ball screw, effectively withstanding the axial load generated during operation.

At SYK, we understand the importance of precision in your machinery. That's why we offer different precision classes of support units (C3, C5, or C7) based on the grade of the ball screw utilized in your equipment. Our support units are meticulously crafted to ensure structural stability and reliable performance. Trust SYK to provide you with reliable support solutions tailored to your unique requirements. Any ball screw end support design is welcome to contact us now.

A ball screw support unit, also known as a ball screw support bearing or ball screw support block, is a component used in precision machinery to provide support and guidance to a ball screw. Our ball screw support units consist of crucial components that guarantee optimal functionality, including Bearing Housing, Bearings, Preload Mechanism, and Mounting Arrangement. By choosing our ball screw support units, you benefit from minimized vibrations, reduced backlash, and improved overall accuracy and efficiency in your linear motion system. These units find extensive application in CNC machines, industrial robots, precision stages, and various machinery requiring precise linear motion control.

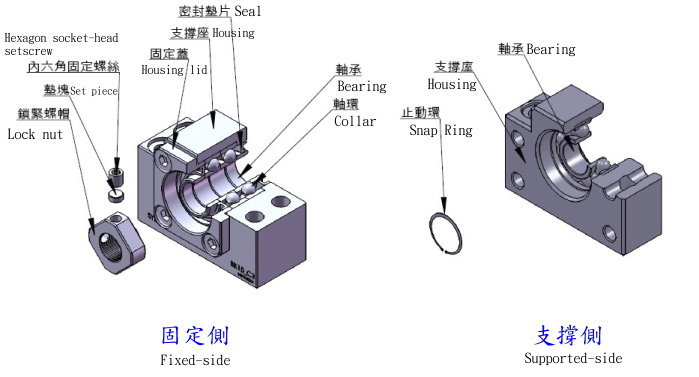

Support units Structure and Features (EK、EF、BK、BF、FK、FF、AK、AF)

Mounting Procedures:

-

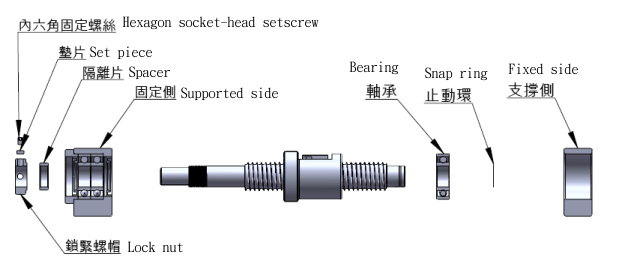

Mount Support unit to the ballscrew shaft

- Mount the fixed-end support unit to the ballscrew shaft.

*Do not disassemble the support unit.

*When inserting the screw shaft into support unit. Please don't scrape the oil-seal lip. - The ballscrew shaft inserting fixed-side, please tighten lock nut with the set piece.

*Inserting the fix-side support unit, lock the lock nut using the set piece and hexagon socket-head setscrew.

When you use it in a special environment, please contact with us. - Mounting bearing of supported-side into the screw shaft, and using snap ring to hold.

Inserting the assembly? into the housing of supported-side.

- Mount the fixed-end support unit to the ballscrew shaft.

-

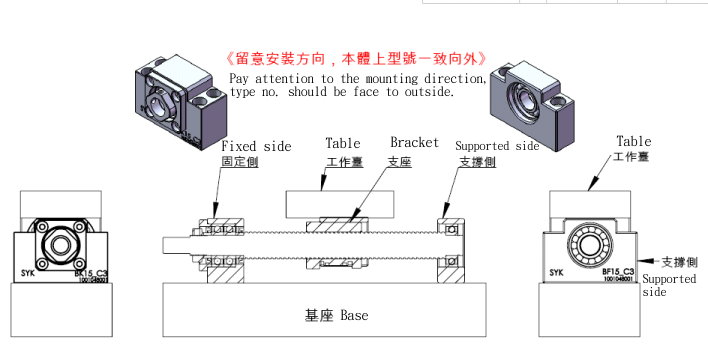

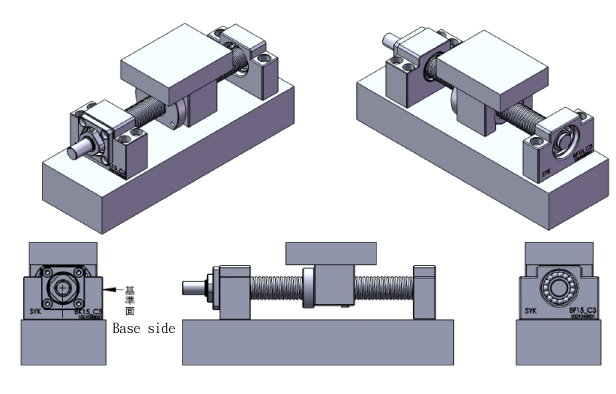

Mounting the table on the ball screw nut and mounting the support unit on the base

- Temporarily fasten the ballscrew Nut to a table. If a bracket is used, insert the Nut into the bracket and temporarily fasten the nut to a table.

- Mount fixed-side into ballscrew shaft. Temporarily fasten the fixed-side Support Unit to the base.

- Mount supported-side into ballscrew shaft and using snap ring to hold. Inserting assembly into supported-side housing.

- Adjust between the table guide face and ballscrew to make sure parallel accuracy.

Meanwhile, fasten the fixed-side and supported-side Support Unit to the base. - Center the ballscrew shaft by moving the table toward the supported-side Support Unit. Adjust the center, checking whether the table moves smoothly by moving it to the right and left a number of times. Then, temporarily fasten the system to the base.

-

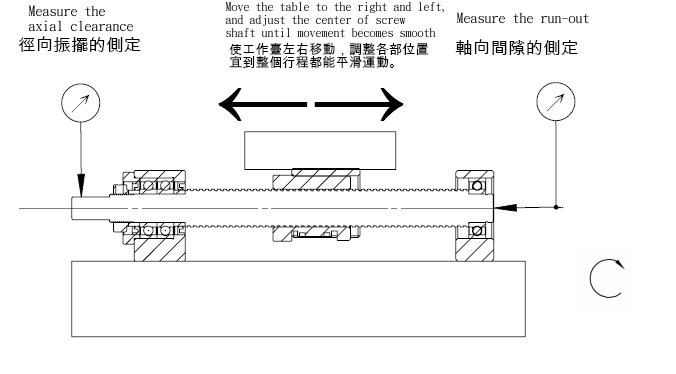

Checking accuracy

To use the indicators, one to check the run-out error at end of the ball screw shaft, and the other to check the axial clearance.

(If you need any information about the axial clearance, please contact to us.)

-

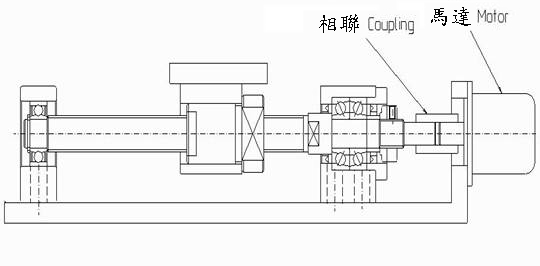

Connecting to the motor

- Fix the motor to the machine.

- Connecting the ball screw with the motor on the coupling.

(When you mount attention accuracy.) - Final, testing the motor operation.