Heavy Load Fixed Side Series

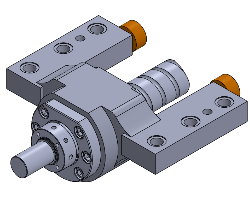

The Heavy Load Fixed Side Series from SYK is engineered to provide robust and precise support for ball screw systems, particularly in demanding machine tool applications. These support units utilize P4 class 60-degree axial angular contact ball bearings for exceptional performance and rigidity. The core of this series lies in its specialized ball screw support bearings and ball screw bearing blocks, which are designed with specific features to optimize ball screw performance.

Key Components: Ball Screw Support Bearings and Bearing Blocks

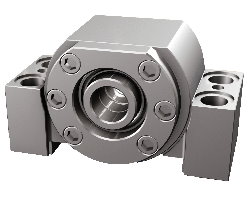

Ball Screw Support Bearings: These bearings are the heart of the support unit, designed to handle significant axial loads while maintaining smooth and accurate rotation. The P4 precision class ensures minimal runout and consistent performance. The 60-degree axial angular contact design is crucial for managing the high axial forces generated by ball screws, preventing premature wear and maintaining accuracy over long periods.

Ball Screw Bearing Blocks: These blocks provide a rigid and stable housing for the ball screw support bearings. Their robust construction ensures that the bearings are properly aligned and supported, maximizing their load-carrying capacity and lifespan. The blocks are designed for easy installation and integration into machine tool structures.

Advantages of the Heavy Load Fixed Side Series

High Rigidity: The design and materials used in this series result in exceptional rigidity, minimizing deflection under heavy loads. This is crucial for maintaining the precision and accuracy of machine tools. The provided rigidity values in the product table are theoretical estimates derived from the elastic deformation between the ball groove and balls, offering a reliable benchmark for performance expectations.

High Axial Load Capacity: Specifically engineered to withstand substantial axial loads, these units are ideal for applications where heavy cutting forces are involved. The permissible axial load is 0.7 times the limiting axial load, providing a safe operating margin.

Preloaded Bearings: The bearings are preloaded to eliminate backlash and increase stiffness. This preload contributes to the starting torque, which is a result of the bearing preload itself (excluding any torque from the seal).

Optimized Design for Ball Screw Support: The functions and structure of these bearings and blocks are specifically tailored for ball screw support applications, ensuring optimal performance and longevity of the ball screw system.

Ready to Use: The bearings are pre-packed with grease, eliminating the need for initial lubrication. An optional oil hole (G) is available for re-greasing, allowing for easy maintenance and extended service life.

Applications: The Heavy Load Fixed Side Series is ideally suited for a wide range of applications, including:

- CNC Machine Tools: Supporting ball screws in CNC mills, lathes, and machining centers.

- Automation Equipment: Providing precise and reliable linear motion in automated systems.

- Industrial Machinery: Supporting ball screws in various types of industrial equipment requiring high precision and load capacity.

- Robotics: Ensuring accurate and repeatable motion in robotic arms and other robotic systems.

Bearing Combinations: DF, DFD, and DFF

- The series offers three different bearing combinations (DF, DFD, and DFF) to cater to various application requirements. These combinations differ in their arrangement of bearings, affecting their load capacity and stiffness characteristics. [It would be beneficial to elaborate on the specific characteristics of each combination (DF, DFD, and DFF) if more detailed information is available.]

By choosing the appropriate bearing combination and utilizing the robust design of the Heavy Load Fixed Side Series of ball screw support bearings and ball screw bearing blocks, users can achieve optimal performance and reliability in their ball screw systems.